History

Silicone hydrogels were first introduced in 1999. This represented a breakthrough in technology in terms of oxygen transmissibility. In a traditional hydrogel material, oxygen diffuses to the cornea by means of dissolving into the water component of the lens. Water itself only has a Dk of 80, and as such there is a limit to the oxygen transmissibility of this material. A typical hydrogel lens with 58% water content has a Dk/t of 25.5 x 10-9.

Silicone hydrogels transmit oxygen to the eye through the silicone, rather than the water component of the lens. This results in much higher levels of transmissibility. They meet the minimum Dk/t criteria for oedema free daily wear with the suggested range being from 24 x 10-9 to 35 x 10-9.1,2 As such the many hypoxic changes that were seen through over wear of hydrogels such as neovascularisation, corneal microcysts, corneal oedema and limbal hyperaemia are a thing of the past when silicone hydrogels are worn.3,4

As our knowledge about oxygen delivery to the cornea has evolved, it is becoming increasingly acknowledged that Dk/t is no longer the best way of comparing the oxygen delivery performance of silicone hydrogels. While it does describe the amount of oxygen passing through a contact lens in laboratory conditions, it does nothing to replicate the on-eye situation. A better understanding of alternative oxygen measurements such as oxygen flux and oxygen consumption shows that in these highly permeable materials, a doubling of the Dk/t does not result in a doubling of the oxygen delivery to the eye.

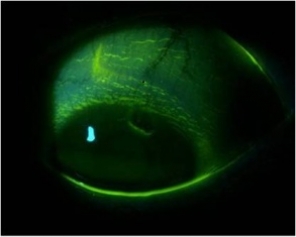

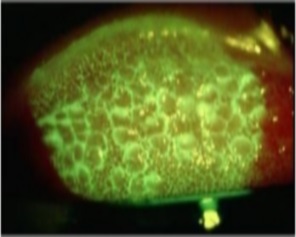

However, in spite of the advancement in oxygen delivery, challenges remained with the early silicone hydrogels with regard to their suitability for comfortable daily wear. Their intrinsically higher modulus have the potential to lead to mechanical complications such as superior epithelial arcuate lesions (SEAL) and contact lens induced papillary conjunctivitis (CLIPC).5

Mechanically induced complications from first generation silicone hydrogels: superior epithelial arcuate lesion (SEAL) and contact lens induced papillary conjunctivitis (CLIPC).

Focus for material development and contact lens selection for patients has now moved towards ensuring the correct balance of material properties are achieved in order to deliver comfort as well as health benefits for the wearer. This section outlines current thinking and new research findings in this important area.

1. Holden, BA and Mertz, GW. Critical oxygen levels to avoid corneal edema for daily and extended wear contact lenses. Invest Ophthalmol Vis Sci. October 1984; 25:10 1161-1167.

2. Harvitt DM and Bonnano J. Re-Evaluation of the Oxygen Diffusion Model for Predicting Minimum Contact Lens Dk/t Values Needed to Avoid Corneal Anoxia. Optom Vis Sci. 1999; 76:10 712-719.

3. Fonn D et al. The ocular response to extended wear of a high Dk silicone hydrogel contact lens. Clin Exp Optom. 2002; 85;3 176-182.

4. Dumbleton KA et al. Vascular Response to Extended Wear of Hydrogel Lenses with High and Low Oxygen Permeability. Optom Vis Sci. 2001; 78:3 147-151.

5. Dumbleton KA. Non-inflammatory Silicone Hydrogel Contact Lens Complications. Eye & CL. 2003; 29:1 S186-189.

Development

Since 1999 there have been many significant developments in silicone hydrogel technology. Silicone is hydrophobic; the first lenses employed a secondary process to manufacture a wettable contact lens surface. In 2004 ACUVUE® ADVANCE® was launched. This and all subsequent ACUVUE® silicone hydrogel products use patented HYDRACLEAR® Technology to permanently embed a wetting agent at the point of manufacture to produce wettable, smooth and comfortable contact lenses.1,2

Silicone hydrogel lenses are now widely available and suitable for the majority of wearers. Lenses are available not only in spherical prescriptions, but for astigmatism and presbyopia too. And 2008 saw the introduction of the world's first ever daily disposable silicone hydrogel lens: 1-DAY ACUVUE® TruEye®.

1. Young G, Riley C, Chalmers R & Hunt C. Hydrogel Lens Comfort in Challenging Environments and the Effect of Refitting with Silicone Hydrogel Lenses. Optom Vis Sci (2007); 84(4):302-308.

2. Riley C, Young G & Chalmers R. Prevalence ocular surface symptoms, signs and uncomfortable hours wear in contact lens wearers: the effects refitting with DW silicone hydrogel contact lenses. Eye and Contact Lens (2006); 32 (6): 281-286.

Drop out

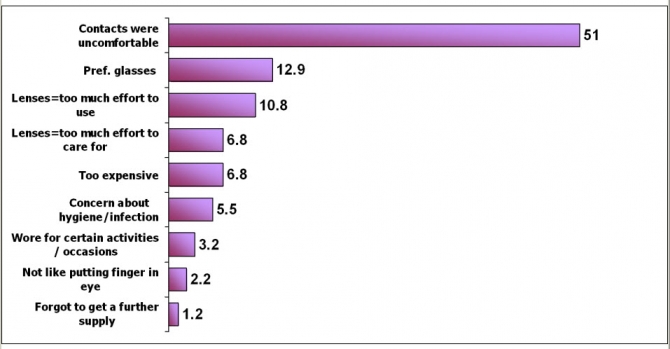

Even with the introduction of silicone hydrogel contact lenses, the most commonly cited reasons for drop out are dryness and discomfort.3,4 A fundamental role of an ideal contact lens would be to cause no change in comfort over the course of the day compared to the natural eye. Ideally the wearer needs to be oblivious to the sensation of wearing that optical device. Two silicone hydrogel materials have been shown to perform, in terms of comfort, as well as the naked eye5 and in front of a computer to give a no-lens feeling.6

It is true however that not all silicone hydrogels are the same: they are manufactured differently; they have differing amounts of silicone and water and they have different material properties such as wettability and smoothness. Better understanding how the balance of properties affects comfort can help us discern between different silicone hydrogel contact lenses and ensure the most suitable options are recommended for the patient.

Main causes of drop out from contact lens wear4:

1. Incidence study UK, Albermarle Market Research, June 2010.

2. 2004 Contact Lens Drop Out Study, 2005 Synovate Consumer Research.

3. Young G, Veys J, Coleman S. A multicentre study of lapsed contact lens wearers. Optom Physiol Opt 2002; 22:516-527.

4. TNS Visiontrak panel data UK 2007.

5. Morgan PB, et al. Ocular physiology and comfort in neophyte subjects fitted with daily disposable silicone hydrogel contact lenses. Contact Lens Anterior Eye (2012), http://www.sciencedirect.com/science/article/pii/S1367048412003311

6. JJVC data on file 2008.